Mechanical and pneumatic conveying at a powerplant

Customers needs

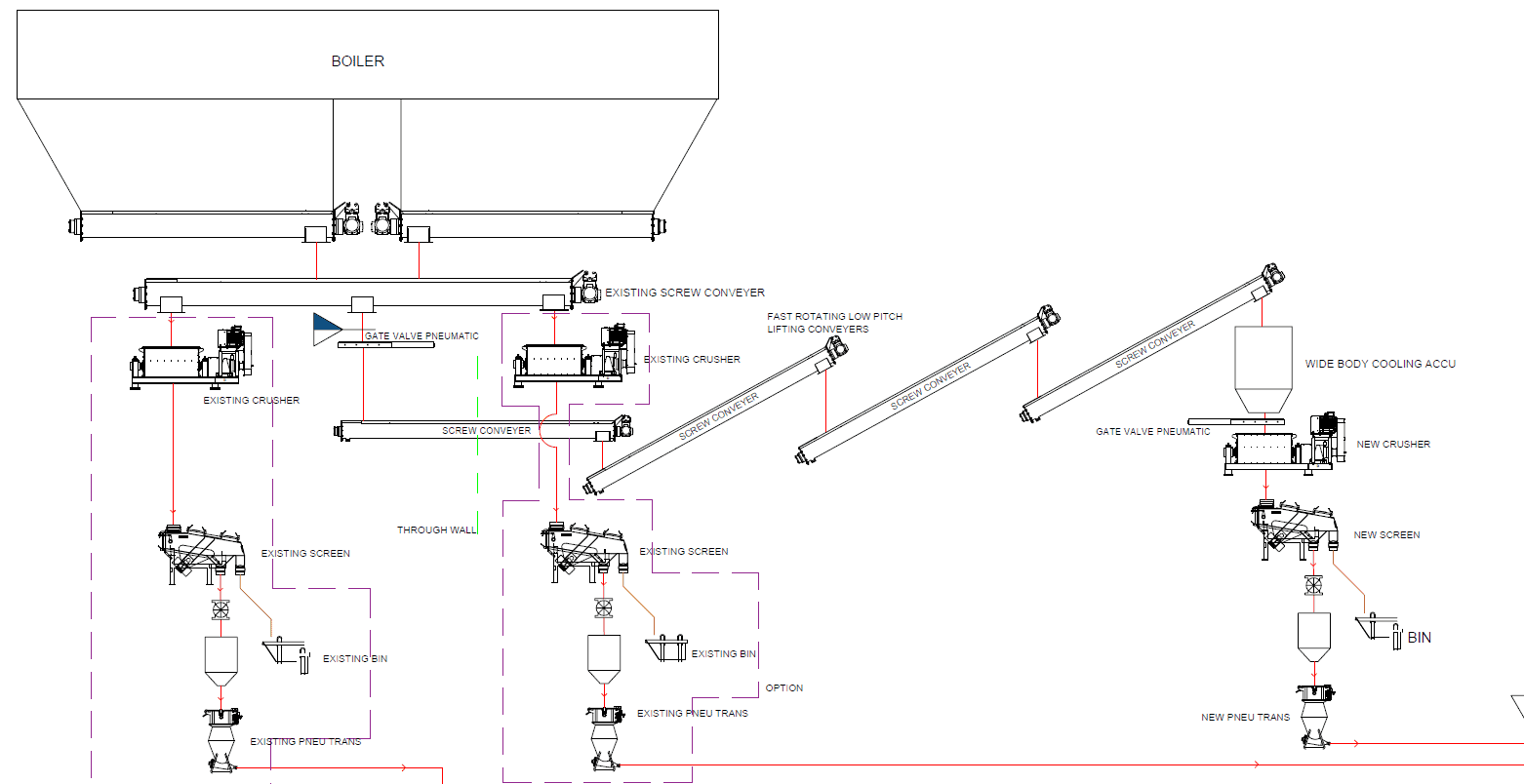

The customer had to renovate his existing system for handling fly ash and slag.

The solution

PAM developed a system for handling the hot fly ash, where it is transported via 4 screw conveyors from the existing collection auger under the boiler, to a temporary cooling tank. Here the ash has the opportunity to cool down to a lower temperature before it is sent on through a crusher, a sieve and further out into a pneumatic conveying system (“dense phase”). The pneumatic conveying system then forwards the ash to a treatment plant or a storage silo.

In addition, PAM developed a parallel system for handling slag from the boiler’s cleaning process. The slag is taken from the same collecting auger under the boiler, but to be able to handle large lumps from the cleaning process, the material in this case is driven directly through a powerful crusher and then further through a sieve and out to another pneumatic transport system.

Mechanical and electrical components incl. control / programming as well as installation and start-up were included in this project (a PAM turn-key solution).

Request assistance

Do you want to learn more about how PAM can assist you on your bulk handling ? Please submit the information requested, and you will be contacted by one of our consultants shortly.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search