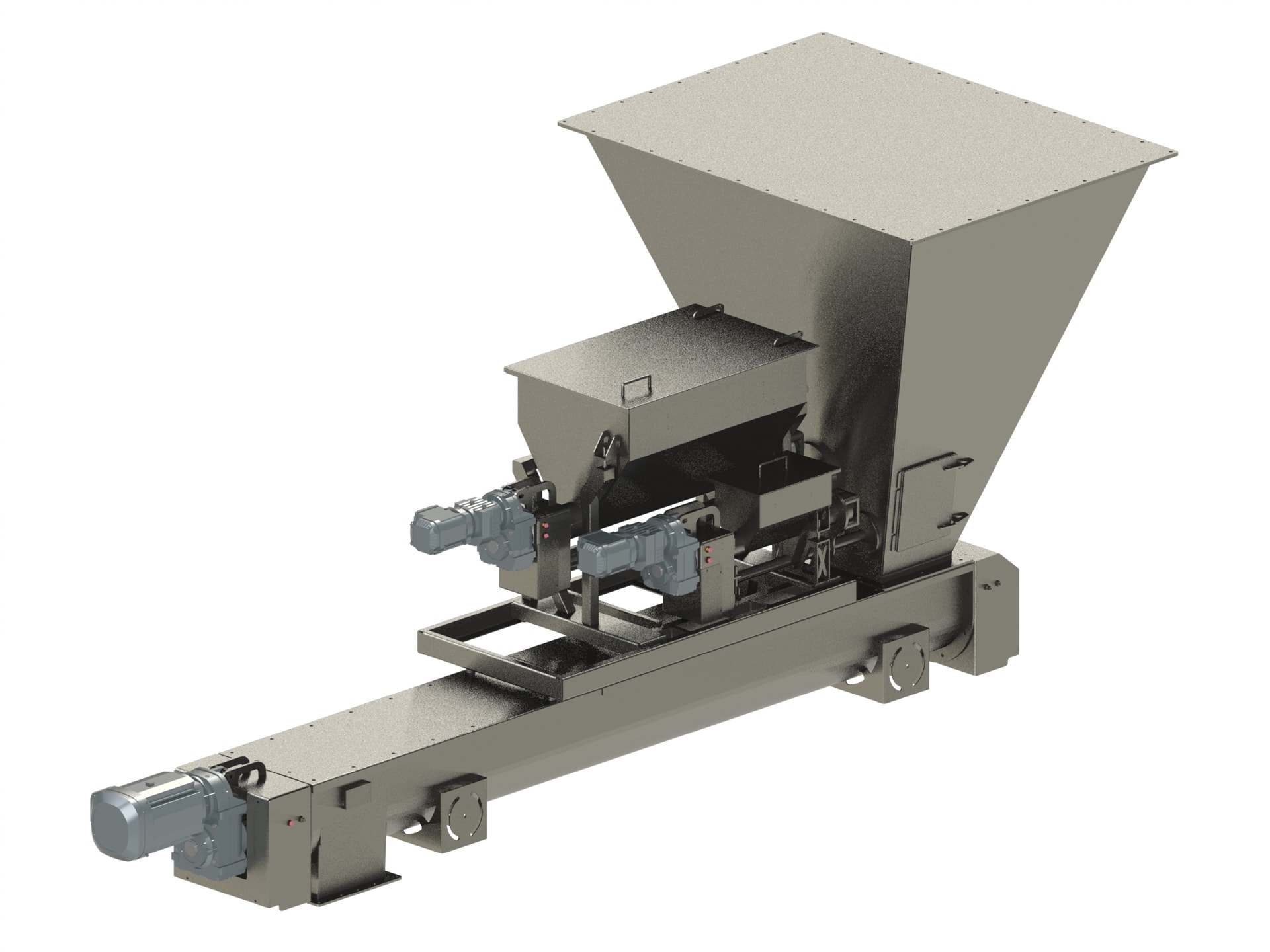

Mini-/Micro dosage system

Customer needs

Based on manufacturing of dry products in the food industry, PAM was asked to deliver a plant for dosage of two additives at 10 kg/hour and 1 kg/hour, respectively.

The additives were to be injected into a matrerial flow of 1500 kg/hour, and ending up in a mixing unit.

The solution

PAM designed a mini-/micro dosage unit to handle accurate dosage, regardless of the amount of material left in the containers.

In each silo there was built in a double screw system to secure absolute even dosage during the entire emptying process. The customer has expressed full satisfaction with the solution and test results have shown excellent homogenity for the dosage process as well as the mixing.

We (Stiesdal SkyClean) can highly recommend a cooperation with PAM, also when technical limitations must be challenged.

On our way through the project, we found PAM’s great innovative power and flexible design department particularly useful, where technical solutions changed with PAM’s intervention.

The challenges we had initially on our project have been made significantly easier because of the cooperation with PAM.

PAM works relentless to ensure their delivered product meets all the criteria required and to ensure the quality is seamless. They are joy to work with.

The PAM solutions most noticeable difference for our operation is how it has improved the efficiency with our storing and loading systems, and ultimately how this has added cost saving benefits to our meal handling operations.

I selected PAM because of their dynamic, professional approach and fine attention to detail. This was further supported with their ability to adapt and provide me with a fantastic solution, for both storing and transporting meal.

PAM helped us designing a new product suitable for our production and the collaboration was excellent all way through, PAM is a very flexible and competent partner to work with.

PAM is good at communicating – they revert quickly on inquiries and this way the dialogue easily becomes very close.

Request assistance

Do you want to learn more about how PAM can assist you on your bulk handling ? Please submit the information requested, and you will be contacted by one of our consultants shortly.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search