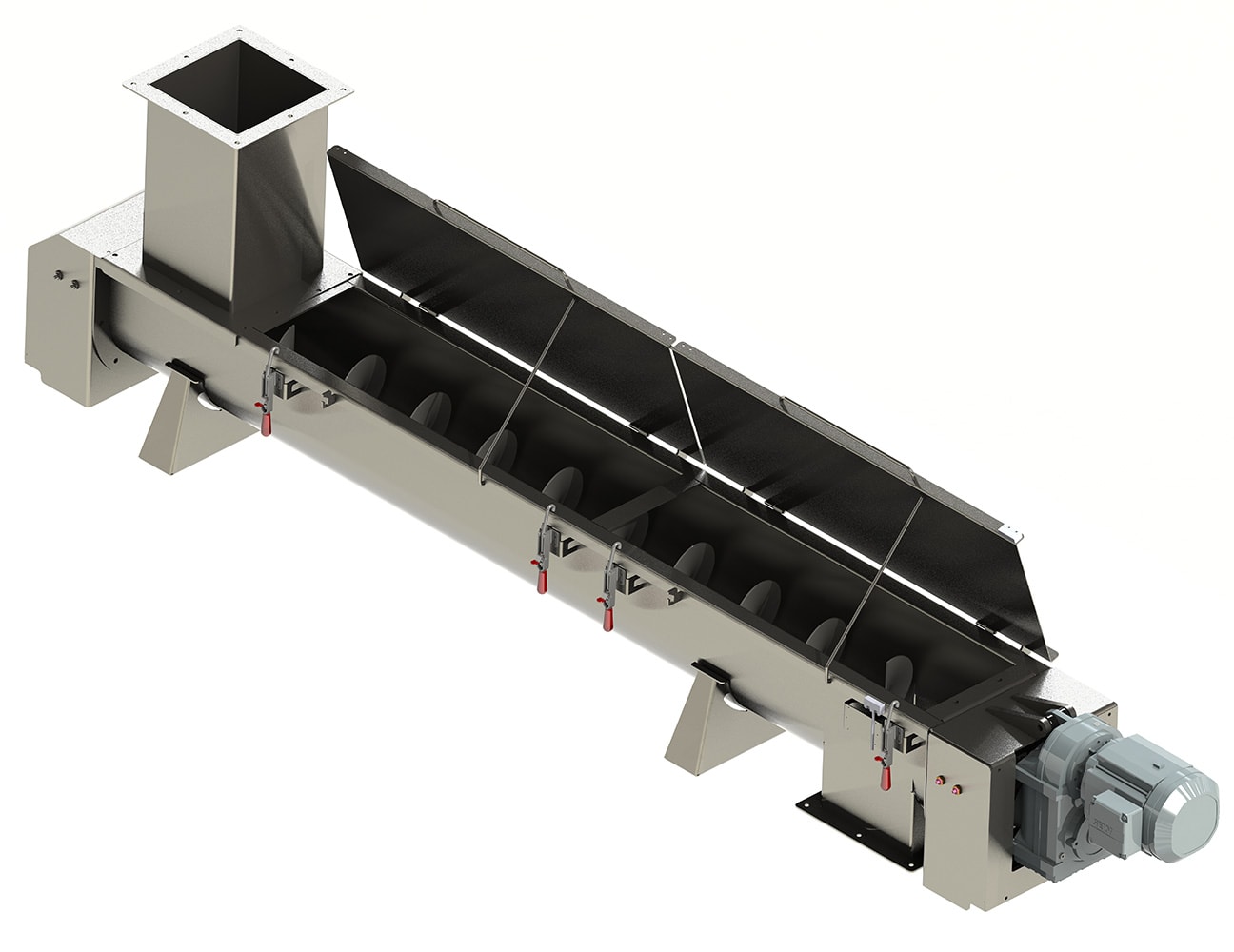

Screw conveyors

We offer industrial screw conveyors which can be combined to a complete mechanical conveying system.

PAM designs and manufactures customized screw conveyors as they are commonly used for mechanical transport of bulk goods. They are broadly used in various industries to convey powders or granules from one point to another. Our product portfolio for screw conveyors includes the following:

Types of screw conveyors from PAM:

- Lifting screws for vertical or oblique transport

- Distribution screws for transport and distribution to multiple outlets

- Dosage screws for dosage of a certain volume

- Extraction screws for emptying of containers

- Pressing screws for transport and dewatering of bulk goods

- Mixing screws for mixing of various bulks in a continuous process or in batches

- Cooling- and heating screws for transport and cooling/heating of your bulk goods in a continuous process

What is a screw conveyor?

A screw conveyor, also known as a screw feeder, is a type of material handling equipment used for moving bulk materials in a linear or slightly inclined direction. It consists of a helical screw blade, called a “flighting,” typically encased in a tube or trough. As the screw rotates, the blade propels the material along the conveyor’s length. This simple mechanism makes screw conveyors versatile and efficient for transporting a variety of materials, including powders, grains, pellets, and other dry bulk commodities. ¨

Screw feeders are widely used in agriculture for moving grain, in the construction industry for cement and in various manufacturing processes for conveying food products, chemicals, and plastics. The screw conveyor’s design allows for controlled feeding at one or more points and can be adapted to handle different materials and throughput requirements, making it a practical and adaptable solution in many industrial settings.

Advantages of using a screw conveyor

Screws conveyors are very versatile and they can be tailored for various applications to make the workflow more efficient for the people working at the facility.

For example, using a dosage screw in a production facility can help companies achieve a more consistent dosage by limiting variance between dosages and thereby reducing waste. Likewise, a mixing screw can be utilized to ensure a consistent blend between materials and limit discrepancies between batches, or similarly be used to create batches with different mixing proportions if required.

PAMs screw conveyors can be supplied in a range of materials, including carbon steel and stainless steel with relevant certificates, such as EX- or Food certificates.

We can of course supply the screw conveyors as stand-alone units, but very often it’s made as part of a system solution including motors, gears and automation.

We can supply screw conveyors as standalone units. However, oftentimes they are included as a part of a system solution, where we deliver a full transport system including rotary valves, shredders, and pneumatic conveying – fully completed with power and automation.

Applications

PAM designs and manufactures transport screws for use in various industries with different purposes. We offer a wide range of screw conveyors

Why choose PAM to supply screw feeders?

At PAM we believe that fast and efficient customer support is the foundation for a healthy business. Hence, we prioritize quick responses and actions in everything that we do. We are dedicated to answering any inquiries within 24 hours in order to maintain a sublime customer satisfaction record. Thus, if you order one or more screw feeders from us, regardless of whether it is standalone or as part of a full system, you can expect assistance throughout the entire process.

With over 85 years in business, we have seen a plethora of cases with a variety of specifications throughout the years. On that basis, our specialists provide you with guidance and advice on how to successfully implement our quality screw conveyors into your specific setup in order to maximize its efficiency.

Tailored & flexible screw conveyor

Our approach to product development has flexibility at its core. We are dedicated to delivering flexible screw conveyors that aid our customers in optimizing their product lines and efficiency. Hence, we offer tailored solutions where we adjust our products to fit your requirements and specifications.

Having collaborated with a plethora of companies within a variety of industries throughout the years, we know that various industries require specific utility, alterations or modifications in order to meet industry regulations. In a product plant layout, proper optimization can oftentimes be the key needed to turn a profit and scale your company’s capacity. These are exactly the goals that we want to aid you in achieving, which is why we strive to deliver competent advisory services and cutting-edge products such as our flexible screw conveyors every single day.

If you are looking for additional information, you can browse the industries that we have extensive experience collaborating with or explore our cases to see how others utilize our products in their production lines.

We (Stiesdal SkyClean) can highly recommend a cooperation with PAM, also when technical limitations must be challenged.

On our way through the project, we found PAM’s great innovative power and flexible design department particularly useful, where technical solutions changed with PAM’s intervention.

The challenges we had initially on our project have been made significantly easier because of the cooperation with PAM.

PAM works relentless to ensure their delivered product meets all the criteria required and to ensure the quality is seamless. They are joy to work with.

The PAM solutions most noticeable difference for our operation is how it has improved the efficiency with our storing and loading systems, and ultimately how this has added cost saving benefits to our meal handling operations.

I selected PAM because of their dynamic, professional approach and fine attention to detail. This was further supported with their ability to adapt and provide me with a fantastic solution, for both storing and transporting meal.

PAM helped us designing a new product suitable for our production and the collaboration was excellent all way through, PAM is a very flexible and competent partner to work with.

PAM is good at communicating – they revert quickly on inquiries and this way the dialogue easily becomes very close.

Request assistance

Do you want to learn more about how PAM can assist you on your bulk handling ? Please submit the information requested, and you will be contacted by one of our consultants shortly.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search