Depacker and pneumatic conveying

Customer needs

A customer used to spend human resources on manual handling of bags of 15-20 kg/each. The bags were picked up from pallets, after which they were cut open and emptied manually. This way of handling bags put a lot of strain on the person who had the task and at the same time there was a lot of dust in the environment.

Furthermore, some of the dust was very unhealthy, and the customer thus had an obvious business case for investing in a modern system.

The solution

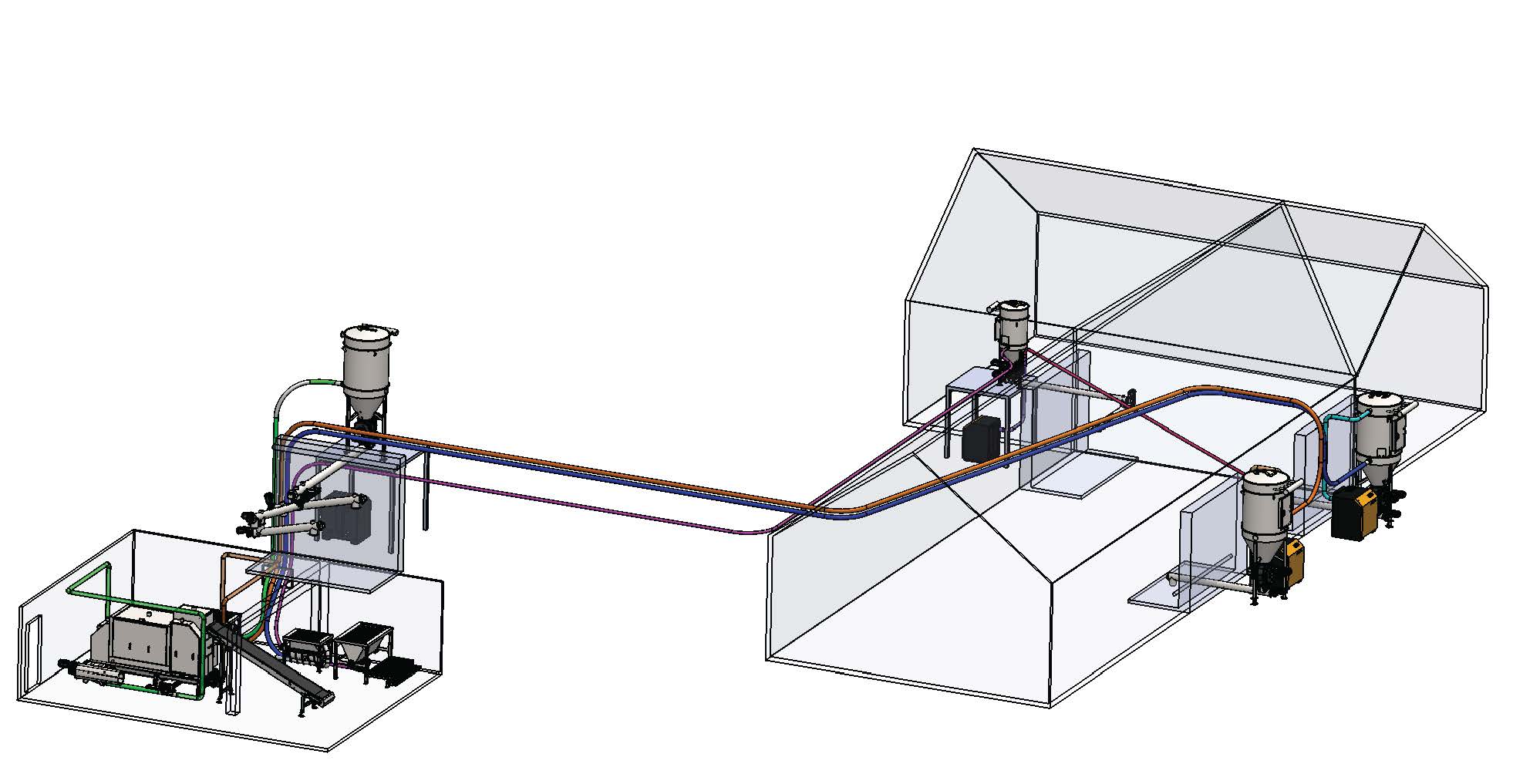

In a close dialogue with the customer, PAM developed a turn-key solution where the bags are automatically opened and emptied by an depacker. The material (powder) is then transported via pneumatic conveying into a filter cyclone. From the filter cyclone, the powder is dosed further into a mixing bin by the use of screw conveyors.

In addition to the filter cyclone, we established an option to use manual discharge tables for a few other types of powder, which are not harmful to health and only handled in small quantities. Also from these discharge tables, the powder is conveyed pneumatically to three other filter cyclones, where it is dosed further into a mixing bin by the use of screw conveyors.

PAM was responsible for the delivery of the complete system, as shown in the sketch.

See more about the individual machines used in this solution (click on the links below):

Request assistance

Do you want to learn more about how PAM can assist you on your bulk handling ? Please submit the information requested, and you will be contacted by one of our consultants shortly.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search