Automatic debagger

Optimize your work environment and save money with automatic emptying of bags

A significant improvement in the physical work environment!

With the automatic debagger, you avoid repetitive work with handling bags, and at the same time you avoid a dusty environment caused by the emptying process.

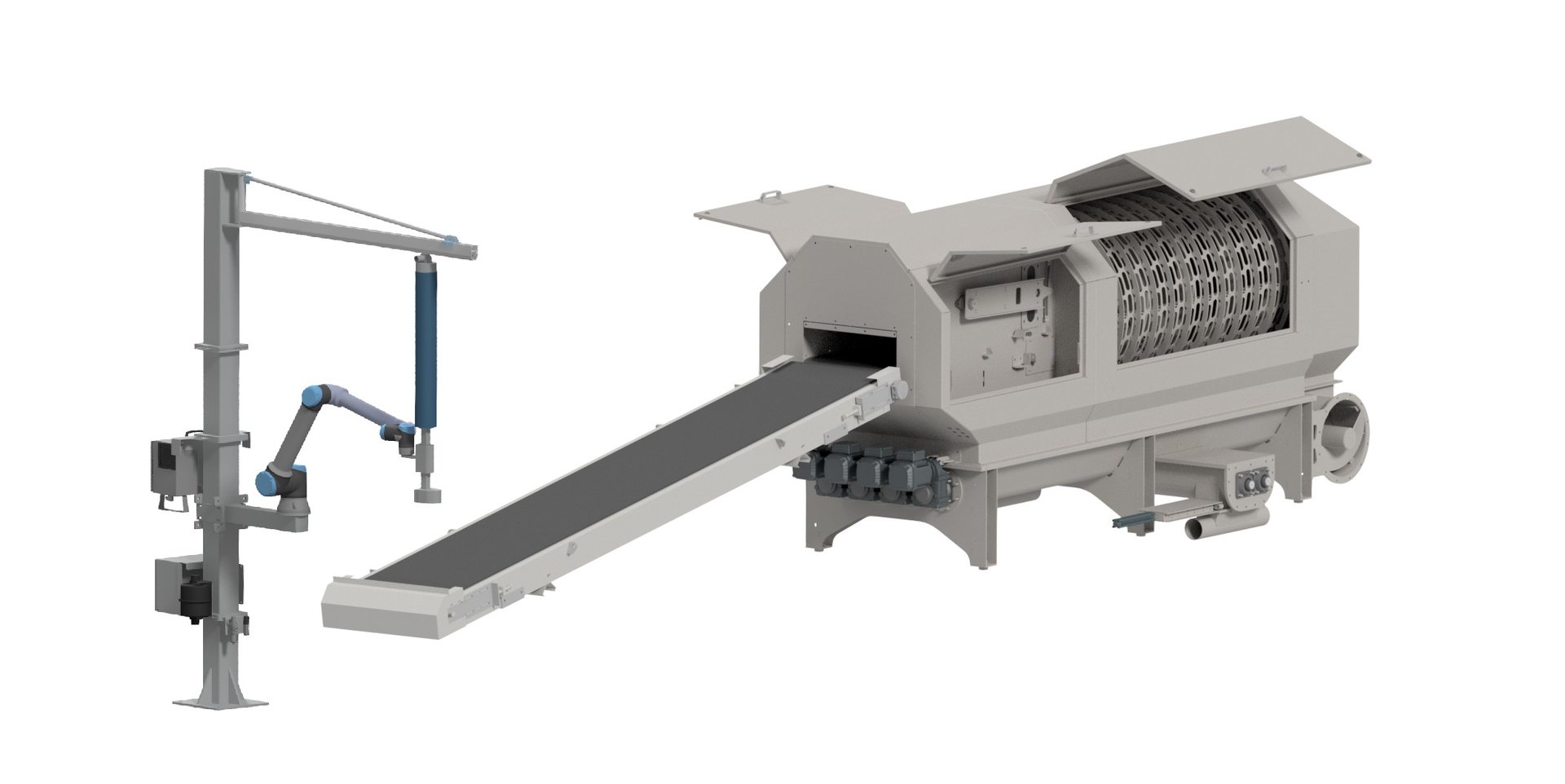

This automatic debagger empties your bags from powder/granules (bag sizes from approx. 2-25 kg/bag). Place the bag on a conveyor belt located at the inlet of the machine, and a few seconds later the empty bag and the bag’s contents are separated, without the use of human handling. The debagger can of course be delivered with an automatic in-feed system, by the use of robotic technology. So all you have to do is to place a pallet of bags next to the machine.

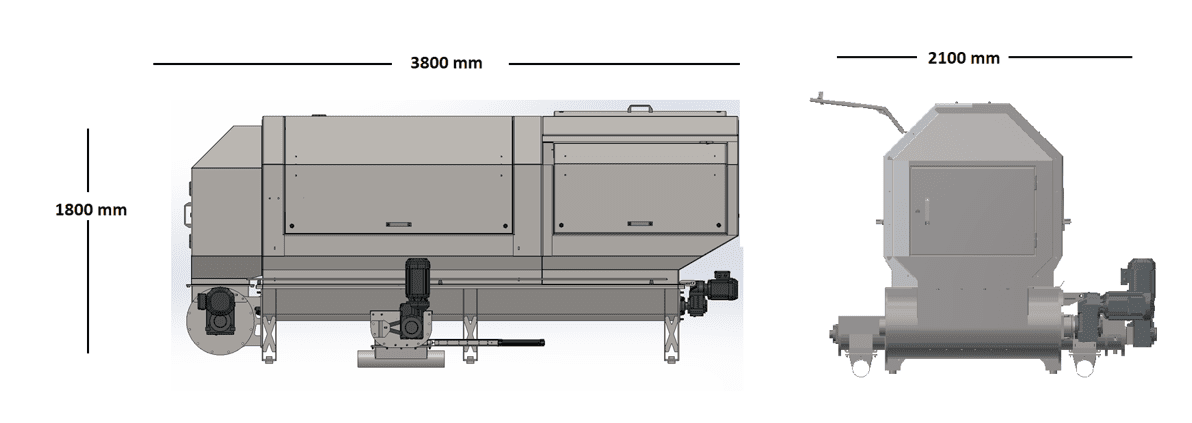

Specifications:

- Capacity up to 16 t/hour – depending on the nature of the medium

- The machine is connected to a vacuum, whereby dust from the emptying process is avoided

- The empty bags are collected in a reservoir on the side of the machine

- The powder/granules are conveyed pneumatically or mechanically

- The modular machine means easy possibility for standardized adaptation of design, so that the machine can be easily adapted to your specific requirements for installation and use

- The machine is supplied with complete control and the possibility of integration into existing central control as required

- Can be supplied in a version suitable for Food Ingredients as well as environments with Ex-requirements

We supply automatic debaggers as singular machines. However, most of the time they are included as part of a system solution, where we deliver a full system, including rotary valves, screw conveyors, shredders, and pneumatic conveying – fully completed with power and automation.

Check one of our cases here: Handling of powders in chemical industry

Request assistance

Do you want to learn more about how PAM can assist you on your bulk handling ? Please submit the information requested, and you will be contacted by one of our consultants shortly.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search