Raw materials and building materials

Solutions for efficient handling of cement, gravel and more.

At PAM you can acquire Rotary Air-locks, gate valves and system solutions for the building industry and raw materials handling.

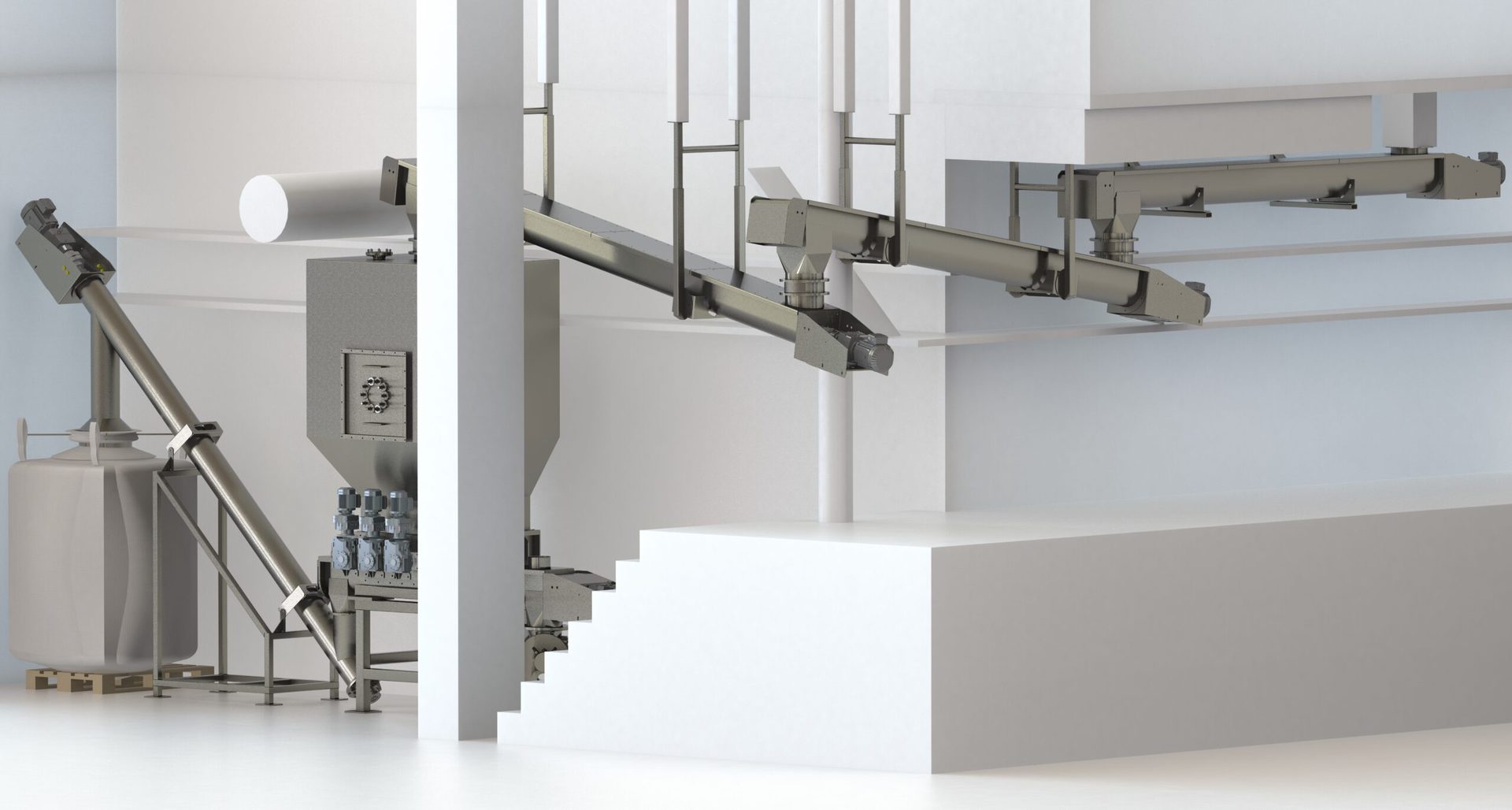

We deliver a wide range of standard components and engineered solutions for handling of bulk goods within the building industry, and for the raw material industries supplying to the building industry. This includes powder as well as granulate.

The materials we handle are often characterized by applying significant wear and tear to the equipment. This is of course something we have considered already in the design phase, and the result is a very robust product which are able to “survive” in the tough environment.

We have extensive experience within the building industry. We know the requirements, and with our own engineering team and modern production- and test facilities we secure a very high level of quality in our solutions.

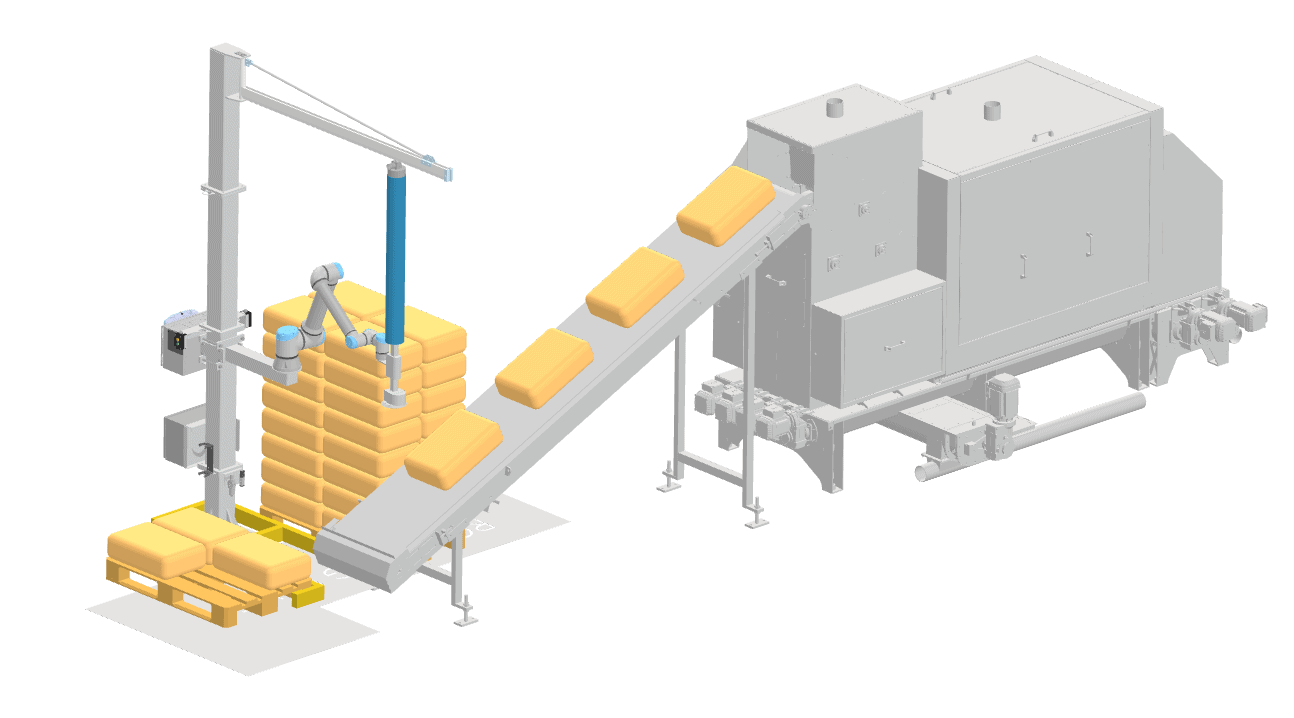

Automatic bag emptying machine

PAM has developed a bag emptying machine which can work semi automatic of fully automized, depending on the needs. The machine is made to do automatic and dust-free embptying of bags containing powder or granulate. If a robot solution is applied, this machine can do the job 100% automatic.

The machine offers obvious improvements in the work invironment by eliminiating heavy and repetitive work. Furthermore, the machine also enables you to empty bags containing harmful powder/chemicals without having any risk of contamination to people.

In Denmark and other countries, it has become a requirement when handling Titandioxid (TiO2) which is a component in paint, that equipment is installed to avoid contamination to humans.

If you are interested to learn more about this bag emptying machine, please contact CEO, Joakim Haulrik.

We (Stiesdal SkyClean) can highly recommend a cooperation with PAM, also when technical limitations must be challenged.

On our way through the project, we found PAM’s great innovative power and flexible design department particularly useful, where technical solutions changed with PAM’s intervention.

The challenges we had initially on our project have been made significantly easier because of the cooperation with PAM.

PAM works relentless to ensure their delivered product meets all the criteria required and to ensure the quality is seamless. They are joy to work with.

The PAM solutions most noticeable difference for our operation is how it has improved the efficiency with our storing and loading systems, and ultimately how this has added cost saving benefits to our meal handling operations.

I selected PAM because of their dynamic, professional approach and fine attention to detail. This was further supported with their ability to adapt and provide me with a fantastic solution, for both storing and transporting meal.

PAM helped us designing a new product suitable for our production and the collaboration was excellent all way through, PAM is a very flexible and competent partner to work with.

PAM is good at communicating – they revert quickly on inquiries and this way the dialogue easily becomes very close.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search