Rotary valves

Rotary valves are mechanical devices used to control and regulate the flow of powders, granules, and other dry bulk materials in your industrial process system. They direct material flow and prevent backflow, ensuring accurate metering and uniform discharge. Rotary valves are used in many solutions for bulk handling. Check our cases for Pneumatic conveying of fishmeal or Mechanical and pneumatic conveying at a power plant.

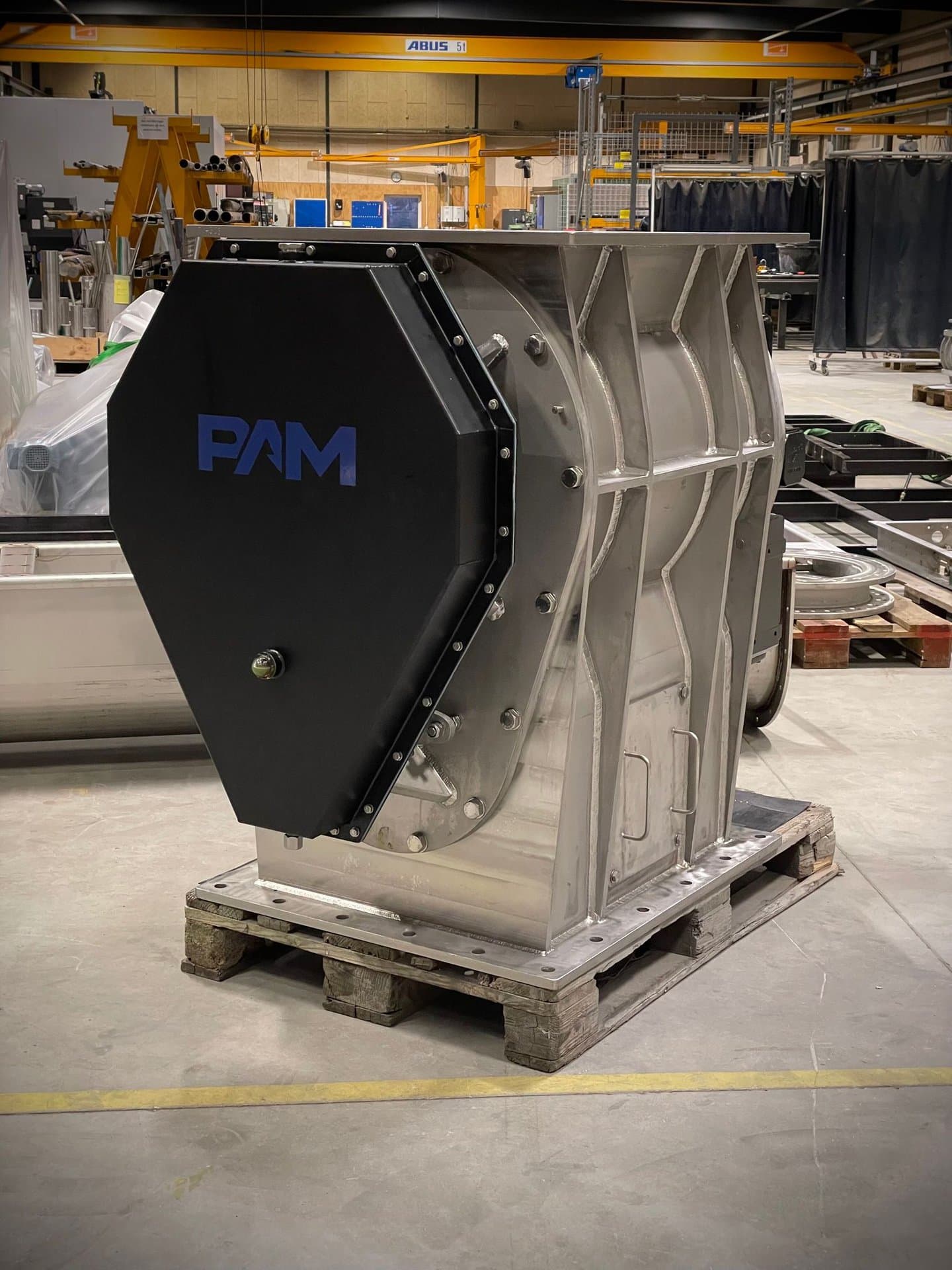

PAM wish to contribute to reducing CO2 emissions. With our rotary valve type UL you can save both money and CO2! These savings are due to the ability to reuse the robust rotary valve up to 5-6 times before you need to buy a new one. At that time, the rotary valve may have been in operation for 25-30 years.

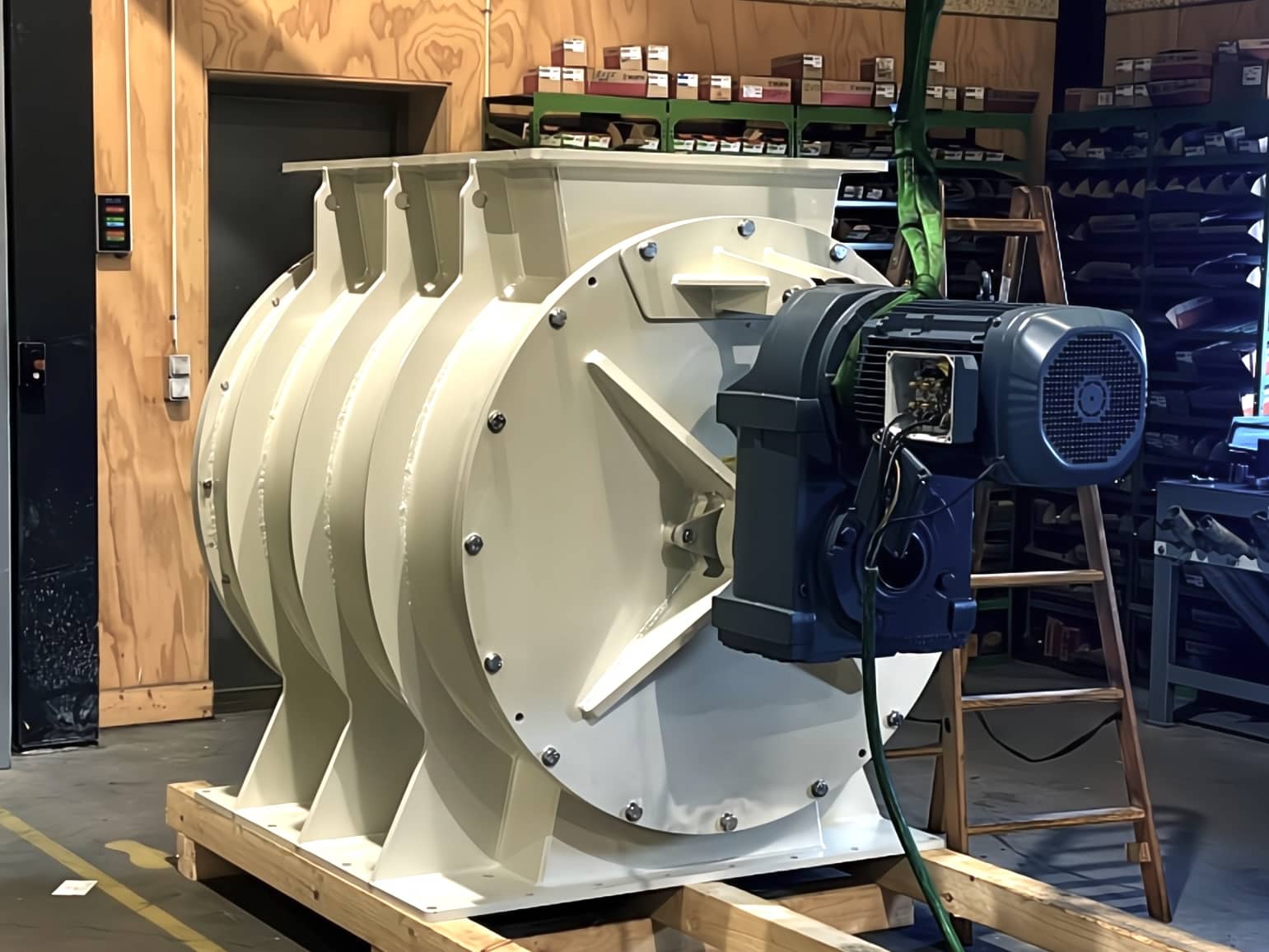

Our rotary valves are widely used across industries, and delivered in various materials such as black steel or stainless materials. We also offer sanitary rotary valves.

We can supply rotary valves as singular units. However, oftentimes they are part of a system solution, where we deliver the full transport system, including screw conveyors, cyclones, shredders, and pneumatic conveying – fully completed with power and automation.

On this page you can see our selection of standard rotary valve, which we usually have in stock for fast delivery!

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

What is a rotary valve?

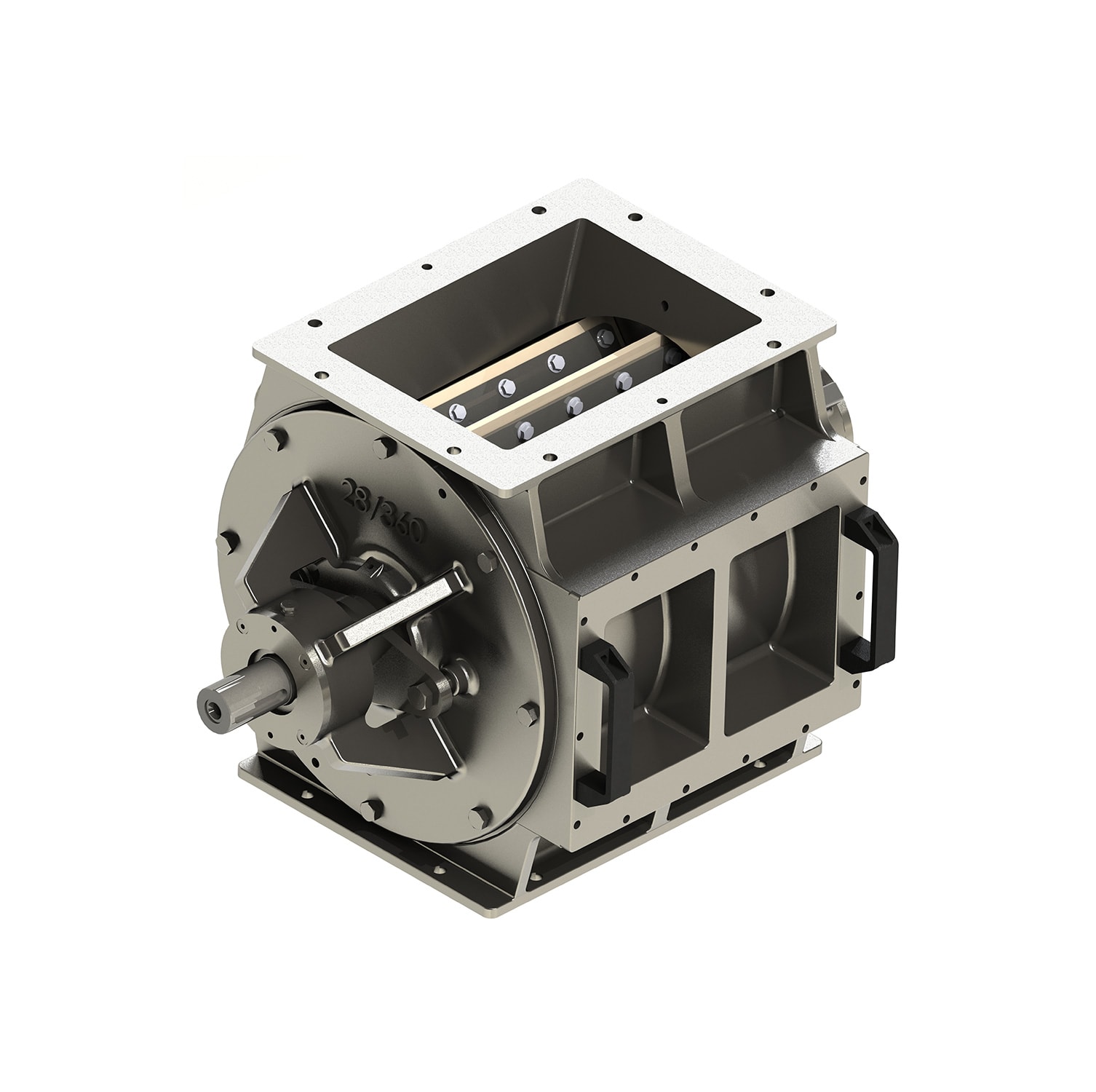

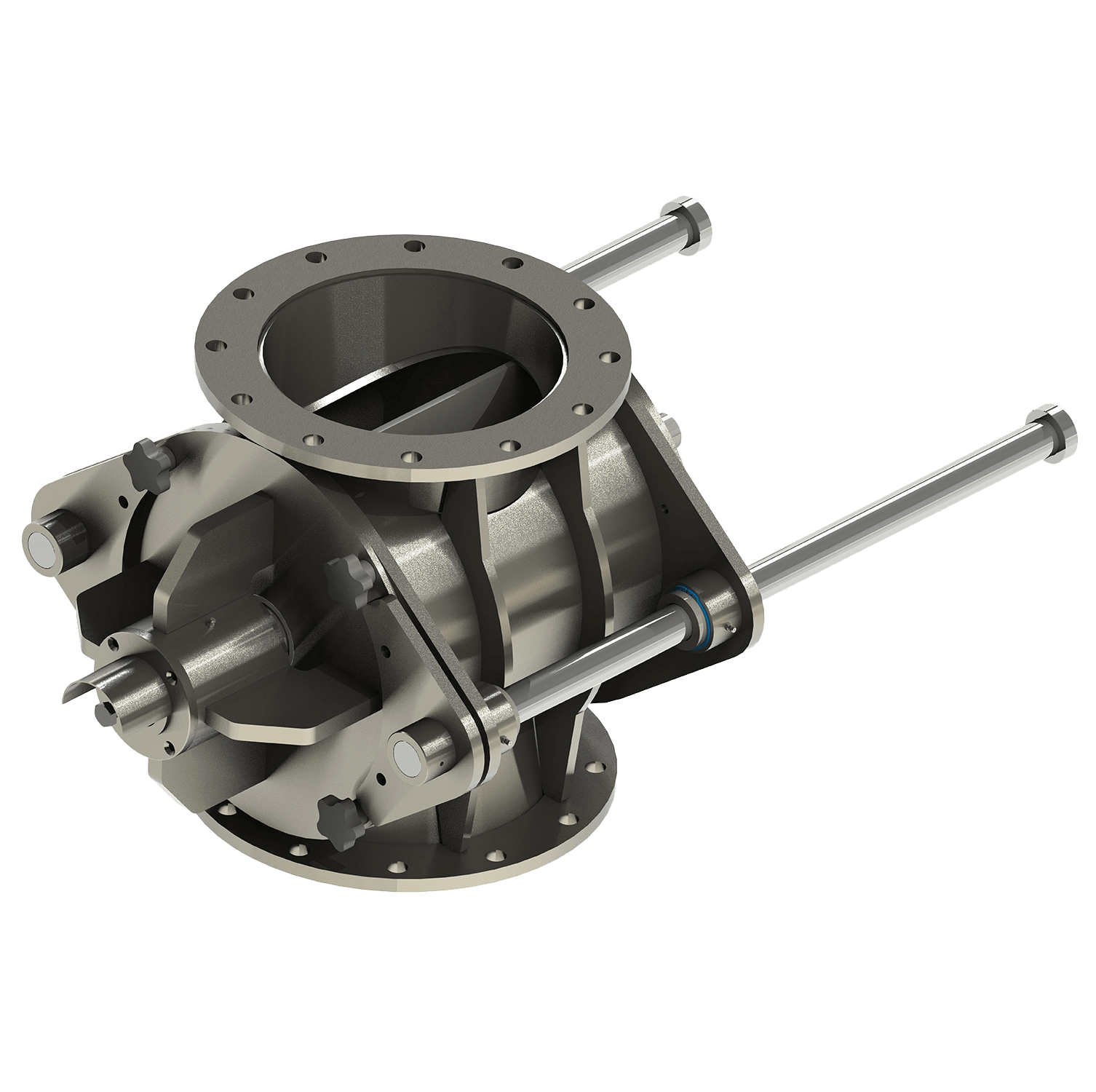

A rotary valve is a versatile piece of machinery in the category of pneumatic valves that can be used for a variety of purposes in industrial production facilities. The four essential components of a rotary valve are an outer housing, a rotor, a rotor bearing, and a drive. However, the valves can be fitted and customized with various other applications to fit a particular purpose or system. They are typically used to transport, regulate and control the flow of dry bulk materials in industrial process systems. While they are most commonly used for dry product they can also be used for slightly sticky or moist products. Rotary valves can be tailored to specific needs and production lines, ensuring that the practical application of the valve is optimized to the specific product in question. This versatility is essential as different product lines may require vastly different specifications and requirements depending on which product is being handled.

Generally, a product is fed into the valve, where it is dispersed equally into the pockets between rotor vanes. Followingly, it is dispersed in equal proportions at the outlet. Thus, the dispensing of product can be tightly controlled, and material loss can be significantly reduced by utilizing a rotary valve in your system. It is important to consider how the valve is implemented into a system. Factors such as which product is being handled and how fast the valve should rotate are essential parameters to scrutinize to ensure that every component of the valve such as rotor blades and motor speed are adjusted to fit the requirements of your production line.

Rotary air-locks in pressurized systems

One of the most common uses of rotary valves are as airlocks in pressurized systems. By using a rotary valve to dispense product in packaging onto a conveying system, pressure loss can be minimized. Likewise, if you run a production system where there is a pressure difference between the upstream and downstream system, this pressure difference can be easily maintained by using a rotary airlock to transport material from upstream to downstream machinery. Furthermore, this isolates the production system from any contamination from the outside environment and acts as a fire/explosion barrier between the pressurized system and the rest of the production facility. This is highly beneficial as it facilitates a safer and more controlled production.

What is a rotary valve used for?

Rotary valves are versatile in their application and can be utilized for a variety of industrial purposes.

A rotary valve can be used to:

- Empty bulk material from silos or other containers of various sizes.

- Collect dust from production lines and discharge into an appropriate container or system to limit dust spreading into the surrounding environment.

- To control discharge from cyclones, screw feeders, or mixers.

- Regulate the dispersion of bulk material.

- Act as an air-lock to control pressure between different system.

- Limit material loss and wastage.

- Feed material into screw feeders or conveyors.

- Fill various types of containers such as sacks, bags and drums.

WHAT ARE THE ADVANTAGES OF USING A ROTARY VALVE IN YOUR PRODUCTION?

As listed above, Rotary Valves can have a wide range of uses in production lines and facilities. They are typically used to precisely control the flow of powder and granules but can be used for a variety of purposes and products in industrial bulk handling. In dry bulk handling, the rotary valve is commonly used to regulate the input of material from one system to another, oftentimes from upstream to downstream.

Our valves ensure a continuous and smooth flow of product in a controlled manner which ensures that your production line will continue running without interruptions. No matter which material you want to transport – our valves will be adjusted to handle the appropriate material in the flow speed that fits your production setup and needs. Similarly, we also offer valve options that can handle sticky material as opposed to the regular dry material, as well as valves that can maintain pressure differences between different machinery. Likewise, our rotary valves are suitable for dairy and food applications, where hygiene is of utmost importance.

Implementing a rotary valve in your production line allows for precise discharging and dosing according to your needs and requirements. This facilitates a steady and precise material-flow without backflow, thus allowing you more accurate dosing and less material loss during transport and production.

Our valves can be used to empty large quantities of material from storage units such as silos and into another holding unit or production line. Using valves for this purpose reduces material loss during emptying and ensures safe discharge with substantially limited risk of accidents.

Should you require clarification on the use of rotary valves or have questions regarding their implementation in your specific production, do not hesitate to contact us.

Your trusted rotary valve supplier in the United Kingdom

Having been established in 1935, we have conducted many successful deliveries and implementations in the UK over the years. We have solid relationships with many large manufacturers all throughout the United Kingdom, who have achieved great results by implementing PAM rotary valves into their production lines.

We work closely with our UK partners to ensure that the valves that they received are tailored specifically to be effective and optimize product flow in their particular production line. Hence, we consider which material you primarily work with, and how best to integrate and implement the valve in your product flow. We offer fast shipping all over the United Kingdom, ensuring that you receive your new valve as fast as possible, allowing you to see the new and improved results almost instantaneously.

Our selection of rotary valves provides value and flexible handling of bulk product in any industrial production facility. Our valves can be customized to fit perfectly in your setup and make your product handling seamless. If you have any questions regarding your particular setup please reach out, and we would be happy to help with identifying your possibilities.

Using a Rotary Valve as an Airlock

One of the primary functions of a rotary valves, also known as rotary feeders, is to serve as an airlock between different parts of the production line or system. Thus, it plays a critical role in maintaining efficiency and functionality.

In pneumatic systems, it’s crucial to keep a consistent air pressure differential between different system parts. A rotary valve effectively maintains this differential by acting as an airlock. It allows material to pass through while preventing significant air leakage. This is essential in both pressure and vacuum pneumatic systems for ensuring efficient material flow and minimizing energy loss.

Rotary valves are excellent for controlling the rate at which material is fed into or out of the conveying system. This precise control is vital for processes that require a steady, consistent flow of material. It helps in maintaining a uniform process downstream and can be critical for operations that require meticulous metering and batching.

By controlling the flow of material, rotary valves can reduce the likelihood of product damage or degradation. This is especially important for fragile materials that can be adversely affected by uncontrolled drops or flows. The gentle handling provided by the rotary valve ensures that the integrity of the material is maintained during the conveying process.

Rotary feeders are versatile and can handle a wide range of materials, from powders to granules. They are compatible with different types of pneumatic conveying systems (both pressure and vacuum systems) and can be used across various industries, including food processing, pharmaceuticals, and manufacturing.

The robust design of rotary valves makes them durable and reliable, contributing to reduced maintenance requirements. By minimizing air leakage and efficiently controlling material flow, these valves help in avoiding system blockages and breakdowns, thereby reducing downtime and maintaining continuous operation.

In systems handling combustible or hazardous materials, rotary feeders play a key role in enhancing safety. By maintaining an airlock, they prevent the backflow of air or gases that could create dangerous conditions or lead to explosions.

Follow us on LinkedIn

On our LinkedIn page we share various news and updates about our company.

Search